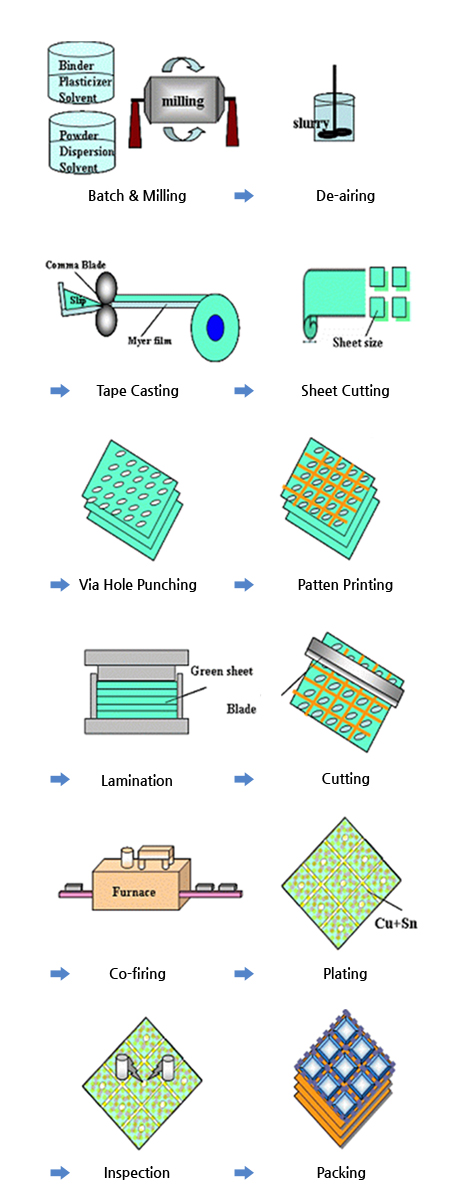

The ceramic powder, the polymer bond, the dispersant and the solvent are evenly mixed.

Well dispersed slurry is produced for moldability.

Mixing Process: The mixer is used to produce physically and chemically uniform slurry.

Dispersing Process: The dispersing equipment is used to apply the repulsive force to internal slurry particles to produce well dispersed slurry.

The process of coating the uniform ceramic sheet on the forming PET film.

Precise control technology on the formed article

Constant slurry feed speed

The best molding speed

Constant drying condition

The process of coating the internal electrode on the ceramic sheet.

For the internal electrode pattern, the W-paste is coated on the ceramic sheet.

The process of repeatedly layering each printed sheet as arranged.

The process of cutting the laminated sheet in the bar state to the predefined size using the blade.

The thermal processing process to make the ceramic package with desired electric and mechanical characteristics.

The formed article is sintered at 1600℃ or higher. The temperature and time profile should be carefully controlled.

Step 1 : Decomposition of the organic material used in the shaping work

Step 2 : Removal of hollow spaces, that is, pores between particles.

Step 3 : Densification and growing particles

Technology metalizing the ceramic and joining it with the metal (Kovar and metallic alloy) by applying the filler metal and the heat (450°C or higher).

The process to form the Ni-Au layer by electric and chemical reactions (electrolytic plating and non-electrolytic plating)

- Ni Plating: External electrode protection and joint

- Au Plating: Joint with the solder

Enhanced solder weldability in the SMT process

Electrode corrosion prevention