Research and Development

Hose

- Basic Theory of Hose

Meaning of Hose (Rubber Hose)

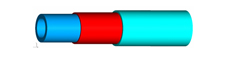

The hose refers to that made of rubber or that composed of cloth covered rubber between fabric strands or inside and outside. Its function is to transport fluid between parts to supply power, coolant, lubricant and fuel to each system.

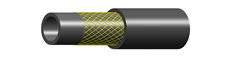

Role of Reinforced Braid

The reinforced braid inserts the reinforced layer between rubber layers to withstand the pressure when the pressure builds in the hose. Depending on the twisting method and the weaving method, the external quality and the durability performance of the hose increase.

Reinforced Braid Unit

Denier : The unit of strand thickness. When the strand length is 450m and its weight is 0.05g, it is 1 denier. That is, the strand weight (g) per 9000m is the denier

Ex) For a 9000m long strand, if its weight is 1000g, it is 1000 deniers and if 1,500g, 1500 deniers.Hose Type

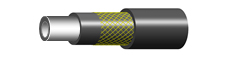

Hose Type NO Structure by Product Type Symbol Product Type 1 Total rubber type - single layered hose 1A

2 Inner layer rubber + outer layer rubber - double layered hose 1B

3 Inner layer rubber + reinforcement layer + outer layer rubber - triple layered hose 3A

4 Inner layer rubber + intermediate layer rubber + reinforcement layer + outer layer rubber - quadruple layered hose 3B

5 Inner layer rubber + THV resin layer + outer layer rubber - triple layered resin hose THV

6 Rubber layer + outer reinforcement layer - double layered outer fabric hose 2A

Test Items by Hose Groups

Test Items by Hose Groups Item Cooling System Fuel System Braking System Steering System Air System Applicable Hose - Radiator Hose

- Water Hose

- Heater Hose

- T/Body Hose

- Reservoir Hose- Vapor Hose

- Return Hose

- Leveling Hose

- Feeding Hose

- Filler Neck Hose- Vacuum Booster

Hose- Power Steering

Return Hose - Power Steering

Suction Hose- ENG Vacuum

- PCV&Breather

Hose - DPF Hose

- I/Cooler HosePerformance Test 1. Bursting pressure

2. Outer diameter variation

3. Air tightness

4. Negative pressure1. Bursting pressure

2. Outer diameter variation

3. Air tightness

4. Negative pressure1. Bursting pressure

2. Outer diameter variation

3. Air tightness

4. Negative pressure(negative pressure leak)1. Bursting pressure

2. Outer diameter variation

3. Air tightness

4. Negative pressure1. Bursting pressure

2. Outer diameter variation

3. Air tightness

4. Negative pressureDurability Test  pressure+vibration

pressure+vibration

+temperature

(antifreeze) FATIGUE &

PVT CYCLE pressure+vibration

pressure+vibration

+temperature

(fuel) Vibratory durability &

IMPULSE vibration

vibration

+temperature HIGH/LOW

TEMP TEST pressure

pressure

+temperature

(power steering oil) IMPULSE

pressure+vibration

pressure+vibration

+temperature

(AIR) Durability test on the hose and pipe assemblyDurable Equipment Coolant durability tester Impulse tester or fuel return tester Vibration durability tester Impulse tester Intercooler hose tester - Rubber HOSE

Hose Definition and Future Development

The recent automotive trend is focused on technologies on small-sized and lightweight body and high powered power train demanded by high performance and low fuel consumption requirements. Consequently, engine vibration and noise of the car, which gets lighter, increase by 10% or more compared to previous models.

The vibration insulation performance improvement of auto parts has emerged to be very important in the sensible vehicle development. Possible ways to insulate solid borne sound are to increase rigidity of the car body or parts, the damper mounted on the transmission and introduction of electronic parts. However, problems are increased fuel consumption due to increased weight and excessive cost increase. Enhanced insulation of the rubber hose,

one of transmission parts, is one of the effective ways for blocking intrusion of solid borne sound. We are focusing on performance enhancement of the rubber hose by continuous new material and new technology development.Hoses by Systems

- Cooling System

- Radiator Hose

- Heater Hose

- Oil Cooler Hose

- T/Body Hose

- Water Hose

- Reservoir Hose

- Steering System

- Power Steering

Return Hose - Power Steering

Suction Hose

- Braking System

- Vacuum Booster Hose

- Air System

- ENG Vacuum

- PCV&Breather

- Hose

- DPF Hose

- I/Cooler Hose

- Air System

- ENG Vacuum

- PCV&Breather

- Hose

- DPF Hose

- I/Cooler Hose

The function of the hose is to transport fluid between parts to supply power, coolant, lubricant

and fuel to each system.

In addition, it has excellent insulation effect on vibration and noise between parts.Related Images

- RADIATOR HOSE

- VACUUM HOSE

- I/C HOSE

- FUEL FILLER HOSE

- WATER HOSE

- VACUUM HOSE

- PCV & BREATHER HOSE

- FUEL VAPOR HOSE

- HEATER HOSE

- RESORVOIR HOSE

- OIL-COOLER HOSE

- FUEL RETURN HOSE