NR (natural rubber) is polyisoprene, the single isoprene polymer, which is a systolic array 1 and 4 where the first and fourth carbon atoms are located at the same side of the double bond. It has outstanding mechanical characteristics and anti-flexibility, but it is vulnerable to environmental conditions such as heat and ozone as well as acids and oils.

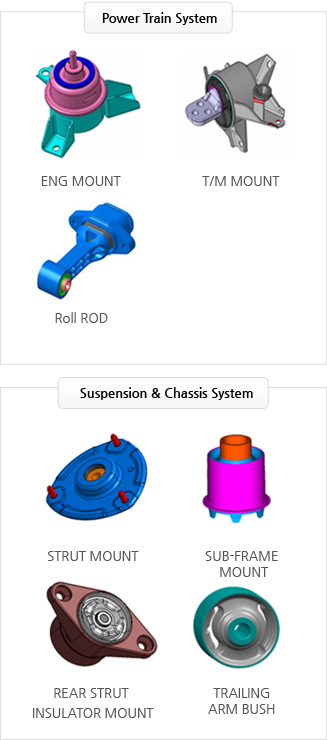

Applied Products: Engine mount, trailing arm bush, etc.

EPDM (ethylene propylene diene monomer rubber) has good tensile strength within the wide hardness range, and it has very excellent ozone resistance, weather resistance, chemical resistance and electric insulation. Its particular strengths are low temperature flexibility, high temperature performance and ozone resistance. Vulcanized peroxide has good heat resistance and compressive elongation up to 150℃.

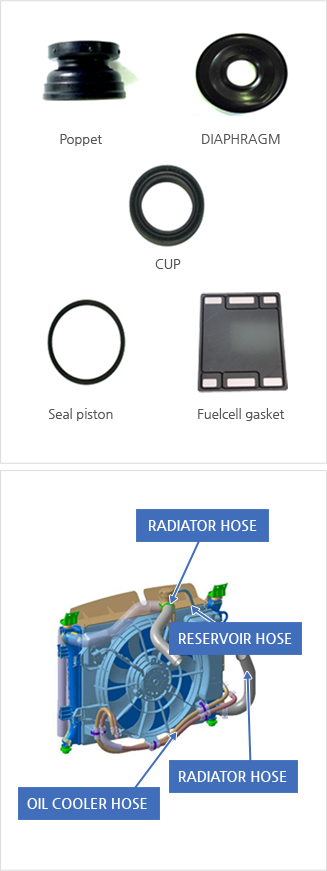

Applied Products: Diaphragm, cup and seal for brakes, gasket for fuel cell vehicles, capacitor seal, etc.

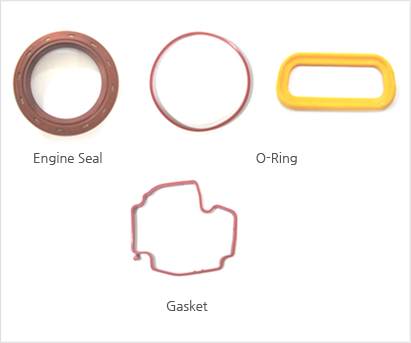

FKM (fluorocarbon rubber) is a high fluoride polymer and it is heat-resistant, ozone-resistant, weather-resistant, flame- retardant, and resistant to oxidative agents. Owing to the C-F bond, the inactive bonding structure with high bonding energy, it is the most heat-resistant and chemical-resistant among rubber materials that are currently commercialized. It maintains rubber elastance up to 200℃ and it is usable up to 300℃ for a short time of period. The triple element copolymer has better chemical resistance and oil resistance than the dual element copolymer, and is used as a highly functional material.

Applied Products : Engine seal, Valve stem seal, O-Ring, Gasket, etc

NBR (acrylonitrile-butadiene rubber) is a copolymer composed of butadiene and acrylonitrile. The higher acrylonitrile content is, the higher resistance to oils and fuel oils is, but the lower rubber elastance and permanent compressive elongation are. As NBR has mechanical and wear characteristics superior to other elastic substances, it is widely used in hydraulic and pneumatic equipment, the vehicle, the vessel, the aviation fuel system, the fuel hose and the hydraulic seal material.

Applied Products : Bearing seal, Shock absorber seal, Hose, etc

Hydrogen added acrylonitrile-butadiene rubber (HNBR) is produced by adding and reacting controlled hydrogen selectively to NBR. The added hydrogen level varies depending on catalyst quantity and reaction conditions. HNBR has very good mechanical properties and it possess excellent resistance to ozone, environmental aging, high temperature air and moisture..

Applied Products : Power steering seal, and refrigerant O-ring for vehicles and home appliances

ACM (polyacrylate rubber) is excellently resistant to heat, oil and ozone. It is a saturated copolymer composed of acrylate ester monomer and bridging monomer. Its key properties vary depending on the raw material rubber type, the bridging monomer and the formation method.

Applied Products : T/M oil seal and O/D-ring

SBR (styrene-butadiene rubber) is a copolymer of styrene and butadiene. Vulcanized SBR has elastance and low temperature characteristics inferior to the vulcanized natural rubber but has heat resistance superior to it. The main operating temperature range is -50℃ to 100℃. It has low ozone resistance but it is possible to improve it by adding the antiozonant. Vulcanized SBR is resistant to non-petroleum automotive brake oil, silicon oil, grease, glycol and water.

Applied Products : T/M oil seal and O/D-ring

VMQ (silicon rubber) is silica reinforced bridging polymer. With its excellent characteristics of weather-resistance and heat-resistance as well as excellent low temperature and electric characteristics, it is usable in the range from -50 to 200℃. In addition, since its fluidity is better than conventional organic rubber, it is easy to process and to color using the pigment and/or the additive. Moreover, since it has low hydrocarbon content, it does not combust easily and its properties change little even if exposed to oxygen, ozone or UV in the air for a long time.

Applied Products : O-Ring, Engine Seal, Gasket, etc

For CR (chloroprene rubber), since its main chain mostly has a perfect trans-1 and -4 structure, it has highly structural regularity. It possesses excellent resistance to ozone cracking, heat aging and strong chemicals, and offers good resistance to silicon oil and grease. Its operating temperature range is between -40℃ and 100℃.

Applied Products : O-Ring, Engine Seal, Gasket, etc

ECO (epichlorohydrin rubber) is saturated aliphatic polyether polymer with chloromethyl side chain. There are three types of epichlorohydrin rubber as follows

- CO : Epichlorohydrin homo-polymer

- ECO : Copolymer of epichlorohydrin and ethylene oxide

- GECO : triple element copolymer of epichlorohydrin, ethylene oxide and unsaturated monomers

ECO rubber is heat-resistant, oil-resistant, ozone-resistant and flame-retardant.

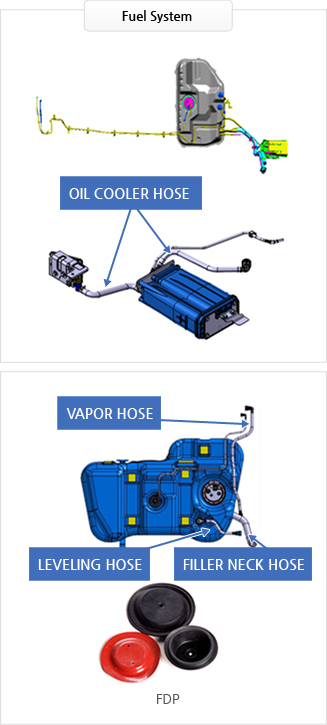

Applied Products : HOSE, FDP